Make your way to SF’s 3D printer

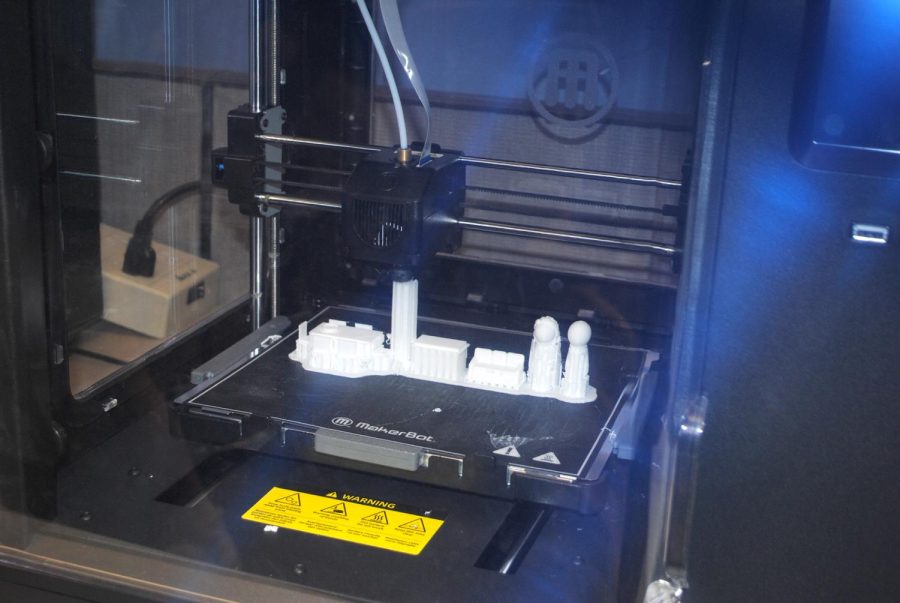

The 3D printer is visible in the Media Center at the Spring-Ford 10-12 Center.

June 21, 2023

Do you want something 3D printed? The MakerBot printers in the Spring-Ford Maker Space have an array of vivid colors perfect for any project. At a low (and ultra-affordable) hourly rate of $1, it’s easy to get your print made on the cheap.

The hourly rate is $1 and offers a selection of densities and infills for maximum strength or weight distribution. To get something printed visit the Media Center and talk to media center specialists Chad Brubaker or Melanie Bowen.

In case you didn’t know, the Spring-Ford Maker Space has a variety of student resources. But today, let’s focus on their two highly advanced MakerBot 3D printers. The MakerBot machines are Cartesian FDM (Fused Deposition Modeling) printers that operate by extruding filament, or thin plastic strings, in set patterns along the XYZ axis. A 3D printer crafts an item layer by layer. It takes hundreds of layers to create a strong lightweight print capable of withstanding force many times its own weight. The two in-house printers, the Replicator+ and Replicator Z18, offer students the ability to create and innovate.

The Replicator+ comes equipped with a flexible bed, Smart Extruder+, onboard camera, and cloud connection. This 3d printer boasts a bed volume of 11.6 inches x 7.6 inches x 6.5 inches. The flexible bed makes even the largest print removal a breeze, while the onboard camera offers a real-time view of the printer’s progress so that one can watch their print get made from anywhere. The equipped Smart Extruder+ is a modular hot end that pairs with the Replicator+. This hot end utilizes a filament sensor to detect filament runout and save the print. This extruder is capable of printing at a max temperature of 446°F. The Replicator+ prints at a speed of 150 millimeters per second and consistently produces quality prints.

The larger of the two, the Replicator Z18, is the evolved Replicator+. This is the taller and more capable version of the Replicator+. This printer comes with a heated enclosure, built-in camera, assisted leveling, and cloud connection. A max temperature of 446°F and an increased build volume of 11.8 inches x 12 inches x 18 inches. It is a definite step up from the Replicator+ and best for those who need large models in a single piece. This printer is equipped with the Smart Extruder+, which prints at a continuous speed of 100mm/s in PLA only.

Students use these printers in and out of the classroom. In class, students may be tasked with replicating broken pieces. After printing, students can then compare in real time what worked and what needs to be changed. What’s more, 3D printers provide overnight prototyping, which is invaluable for hands-on learning and product development.

Not limited to just classroom assignments, teachers sometimes print models for educational examples. In the past, teachers have printed objects like an ancient skull and an asteroid for science classes. In a previous year, a student even designed, and flew a working drone. The student assembled the electronics and then, using the MakerBot printers, created the frame of their model.

These printers can create anything from Star Wars props to headphone holders, video game characters to art pieces. At only a dollar an hour, and with so many available colors, there’s no reason not to stop into the Spring-Ford Maker Space to learn more.